Corrugated Plastic Pipes for Sewerage and Drainage Applications Light weight and long life achievement

Corrugated Plastic Pipes for Sewerage and Drainage Applications Light weight and long life achievement

Long Life Performance

Light in weight but very strong

Less leakage and infiltration

Low operational cost

Rigid Pipes

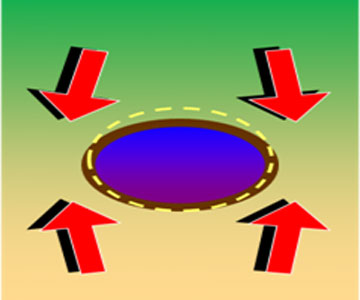

Flexible Pipes

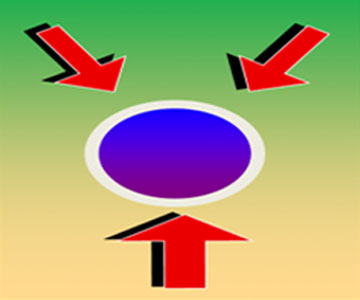

Flexibility

Ecological footprint