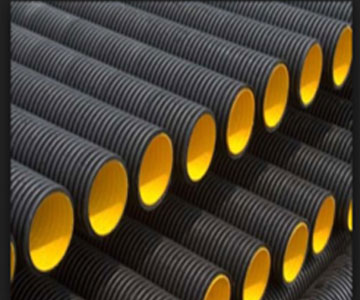

It has been noted down that the use of the double wall corrugated pipe reduces the cost of the project, since the losses owing to the damage is greatly reduced and thus more organizations are looking towards it for the generation of maximum profit. The higher lifespan of the dwc hdpe corrugated pipe makes it more preferable and featuring the maximum load bearing capability makes it stand as the top preferred product for the work. The double wall duct pipe features the corrugated shape and thus offer great strength in the compression resistance. The manufacturing of the double wall duct pipe requires almost the minimum raw material and thus the effect on the environmental aspects is greatly reduced. The product can be thus quoted as having an added advantage over its contemporary pipe.

It has been noted down that the use of the double wall corrugated pipe reduces the cost of the project, since the losses owing to the damage is greatly reduced and thus more organizations are looking towards it for the generation of maximum profit. The higher lifespan of the dwc hdpe corrugated pipe makes it more preferable and featuring the maximum load bearing capability makes it stand as the top preferred product for the work.

The various properties of the dwc pipe make it the best product available in the category. With good corrosion resistance, the longevity of the pipes increases and also the wear and tear decreases. The product is regarded as the safest and chemically inert and is regarded completely safe in regard to environmental damages. Also, featuring a good impact strength, the hdpe dwc pipe has features the smooth inner wall and thus any losses due to friction is at minimum.

With the capability of the double wall duct pipe to bear heavy loads, the product can be easily used in sewage along with all other purposes, which needs to be carried out underground. One feature, in the name of maintaining the shape, even when it is bent, makes it more adorable one for the companies involved in the activities. The feature like easy joining with the use of couplers makes it more comfortable to use and thus offer the operation more speed and the chances of the completion of the task, early increases and thus saving more time and brining in efficiency of the company.

WhatsApp

WhatsApp